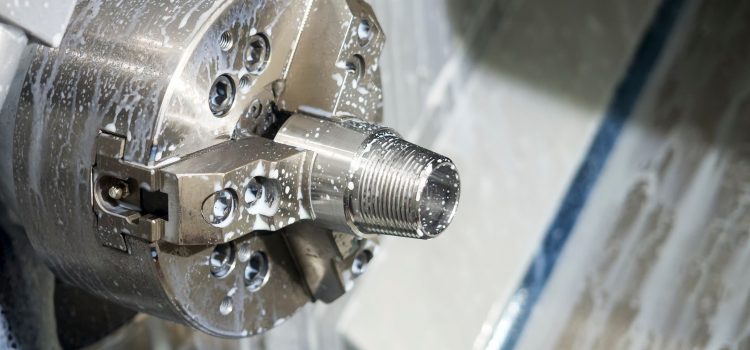

C.N.C. turning part is a type of precision machine product that’s typically make from aluminum or steel. It’s a three-dimensional object that can carve, form, turn, engrave, and/or mill using computer numerical control (C.N.C.) machines. Many industries are heavily involved with C.N.C turning parts, and they may include but certainly not be limited to: aerospace, automotive, biomedical, computer manufacturing hardware or equipment (C.C.H.), and electronics. In this regard, C.N.C. turning part is more specifically known as a cylindrical product. This type of designing and making can further specialized by using an indexable import or selection for the machine’s headstock. Quite often, with C.N.C., these products are make from aluminum. Due to budget constraints that companies tend to place on their projects. Since it’s cheaper than steel but does not have the same risk of rusting as steel. Steel can also a good alternative for C.N.C. turning parts. Since it’s consider to better price than aluminum. But is not necessarily ideal if dealing with this kind of precision manufacturing.

Types of C.N.C. Turning Parts

There are basically two types of C.N.C. turning parts turning parts and machining centers. Turning parts are typically create from medium or high-grade aluminum, while machining centers can make from a variety of materials, including steel and titanium. Turning parts are typically lighter in weight than machining centers and may include but not limited to milling turning. There can also a third type which is highly gear toward the production of mill C.N.C. turned parts. However, this kind does undergo milling first. Then it’s index for more accurate operation in the machine (headstock). The process begins with selecting indices to fit on top of regular machinery minus any collet for turning. Turn mill parts can have a huge range of products made from resin and plastics, such as injection molding to metal plates or alloys that are use in construction or machinery, among many other industrial fabrication purposes.

Machining Process of C.N.C. Turning Parts

The first step in the machining process is to prepare the part for turning. This involves removing any unwanted material, such as metal, that can interfere with the accuracy of the C.N.C. machine and reducing burrs or chips on the surface of the part. Next, a holding fixture is attach to either side of the part so that it can accurately position during cutting. Machining centers can also refer to as C.N.C. Centers or Turn-Mill and are specific machines use for cutting steel up to 18 inches, which subsists quickly into aluminum. These mills have incredibly high vertical travel capability on one axis so that parts can mount over more than 90 degrees of the milling table at any given time. Cutting screws move down into predefine material slots, creating a saw blade for each part. The first piece of metal is typically a plate that need drill, mark, and tap out in its final form. In many cases, these machines are set up with various drilling heads or “drills”. Where you can drill holes up to 3 millimeters deep for mounting screw attachments on the part.

Types of Lathes Used for C.N.C. Turning Parts

There are two main types of lathes use in the turning process vertical and horizontal. Vertical lathes use a headstock that can turn to rotate the tooling around an axis parallel to the work surface. Horizontal lathes use a V-bed where rotation of the workpiece is translate along an axis perpendicular to both the bed and tooling. In general, however, both vertical and horizontal machines require the same setup for turning parts, whereas some are more suits to a certain type of part than others. The tooling for the turning process is often call tools or cutting heads, each of these will typically have multiple phases that make up the complete machining, from placing a start point at first use all the way through to the finish. The phase changes are usually refer to as steps and can include chamfers, slots, and over cuts in addition to drilling holes and tapers, cutting grooves for inserting dowels, etc. Depending on your specialty, loading platforms can specialize to change this phase, but generally, they all require a general machining L.E.D.

Surface Finishing and Marking Techniques for C.N.C. Turning Parts

Once the basic part geometry is complete, it is time to start working on the final finish and any markings that will require. This can include things like etching or, in some cases, milling recesses into parts so they accurately match other components or pieces. There are many types of finishing techniques available, some that are specific to Turning while others are more appropriate for stampings or mold making. The most crucial aspect when chooses a finishing technique is fit the final look and finish are most important. While the majority of us do not have extra materials like glass, diamond, or marble to hand. Which is very expensive, many mediums available easily in small quantities to a hobbyist. If you want an extra polish surface with clear edges. I would suggest using something like computer screen printing ink really only limits by how much waste is leave behind.

Read more…https://goodthing2.com/